Chemical reactors are devices or equipment used in the chemical industry and laboratories to carry out controlled chemical reactions. These devices are specifically designed to allow reactants to mix, react, and produce desired chemicals efficiently and in a controlled manner. There are various types of chemical reactors, and the choice of the appropriate type depends on the nature of the reaction and the goals of the process. Below are descriptions of some common types of chemical reactors:

1. Continuous Stirred Tank Reactors (CSTR): In these reactors, reactants are continuously introduced into a tank and stirred constantly. The reaction takes place in the tank, and the products are continuously removed. CSTRs are used in reactions that require a constant residence time and in steady-state processes.

2. Fixed-Bed Reactors: In these reactors, reactants flow through a solid catalytic bed or solid reactive material. These reactors are used in heterogeneous catalysis processes, such as hydrocarbon cracking in the petroleum industry.

3. Fluidized-Bed Reactors: In these reactors, a stream of gas is used to maintain a bed of solid particles in suspension. They are used in processes involving heterogeneous gas-phase reactions, such as ammonia synthesis.

4. Tubular Reactors: Reactants flow through a long, narrow tube where the reaction occurs. They are used for continuous chemical reactions and allow precise control of temperature and residence time.

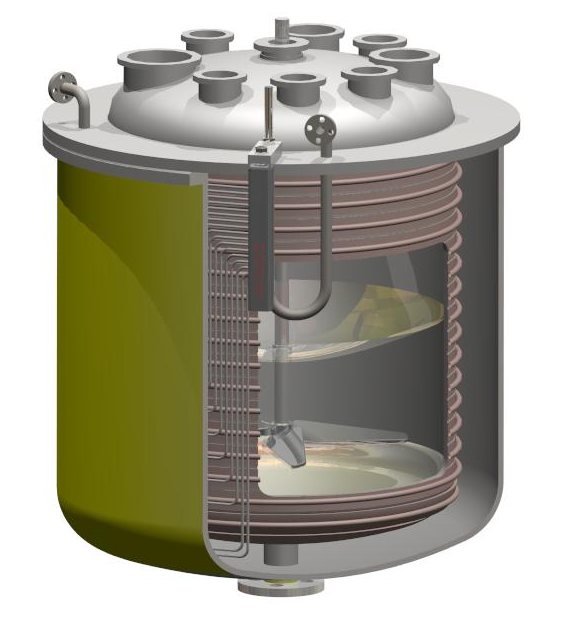

5. Batch Reactors: In these reactors, reactants are introduced in a finite amount and allowed to react for a specific time. Once the reaction is complete, products are removed, and a new quantity of reactants is loaded for the next reaction.

6. Membrane Reactors: These reactors incorporate membranes that selectively allow the passage of certain chemical species, facilitating the separation and purification of products in situations where reactive species or products need to be selectively isolated.

7. Polymerization Reactors: Used in the production of polymers and plastics, these reactors are designed to carry out controlled polymerization reactions.

The choice of reactor type depends on factors such as reaction kinetics, temperature, pressure, phase of reactants, and the need to control reactant concentration. Chemical reactors are fundamental in synthesizing a wide range of chemicals, from pharmaceuticals and petrochemical products to everyday chemicals.

The design of a reactor should be based on the kinetic and thermodynamic study of the intended chemical reaction. Additionally, consideration must be given to the desired production and the characteristics of the raw materials to be used.

Chemical thermodynamics allows us to determine the heat released or absorbed by the reaction, as well as the extent to which the reaction occurs, by calculating the equilibrium constant.

On the other hand, chemical kinetics provides information about the reaction rate and its dependence on concentration, temperature, pressure, and the use of catalysts. Thermodynamics and kinetics provide information about the conditions under which a reaction will take place with acceptable yields and duration.